"Is the solar panel waste issue destined to become a relic of the past?" This intriguing inquiry might seem far-fetched today, but with the rapid advancements in technology, it's a future that may not be too distant. As the solar industry continues its upward trajectory, the challenges associated with recycling solar panels are garnering increasing attention. The National Renewable Energy Laboratory's (NREL) recent breakthrough, employing femtosecond lasers in solar panel recycling, promises to revolutionize the industry, making the prospect of a future devoid of the solar panel waste issue a tangible reality.

Solar panel recycling today is no easy feat. The intricate process of dismantling and separating various materials is fraught with environmental and economic concerns. With an increasing number of solar panels reaching their end of life, the urgency of finding efficient recycling solutions cannot be overstated. The current methods, while useful, fall short in terms of efficiency and environmental friendliness, thereby necessitating innovative solutions to mitigate the burgeoning solar panel waste issue.

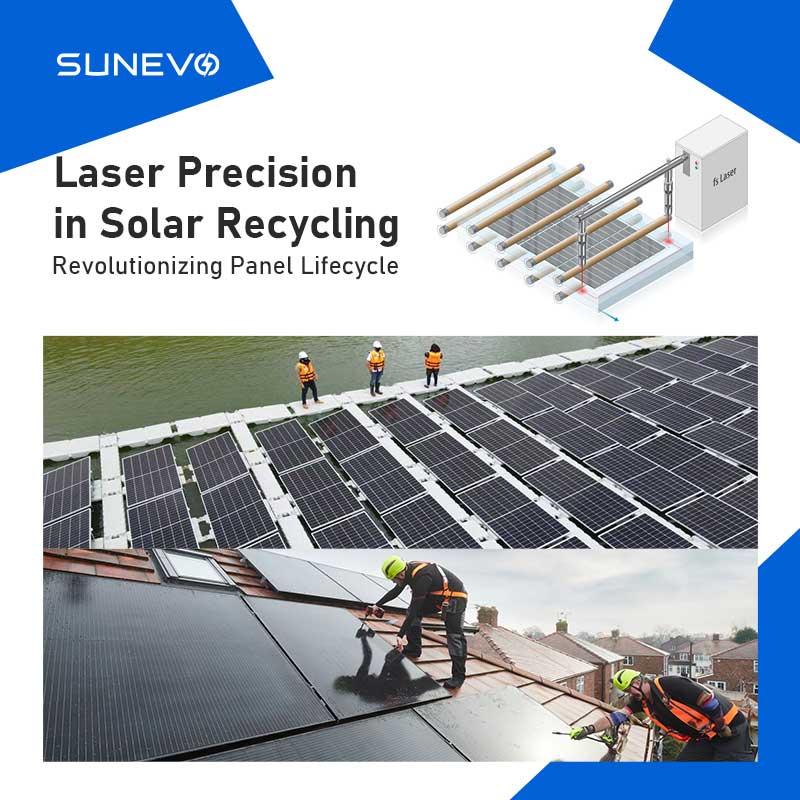

The Innovative Approach: The National Renewable Energy Laboratory (NREL) has conceptualized a cutting-edge method that enhances the recyclability of solar panels by resolving a longstanding issue: the difficulty in recycling materials due to the use of polymer layers. The introduction of femtosecond laser technology—the same used in precise medical procedures like cataract surgery—marks a revolutionary milestone in solar panel manufacturing.

Technology at Work: By employing femtosecond lasers, which emit extremely short bursts of energy, NREL's approach utilizes direct glass-to-glass welds within solar cells. This method focused on a laser pulse lasting a mere few femtoseconds (quadrillionths of a second), which can create hermetically sealed glass-on-glass welds at very high precision.

Implications for Recycling: Traditionally, plastic laminates involved in solar panel manufacturing complicate the recycling process. But now, modules assembled with laser welds can be shattered post their lifespan, enabling users to recycle the glass and metallic components and even reuse the silicon. Such laser welds are "material agnostic," suggesting applicability for various cell materials like silicon, perovskites, and cadmium telluride.

Operational Efficiency: It's crucial to note that the heat from the laser is localized, affecting just millimeters of material, thus preserving the remainder of the cell. Not only are these welds just as strong as the glass they bind, but they also achieve a significant level of durability.

Challenges and Solutions: The dilemma of brittleness in nanosecond laser and glass frit filler welding methods is expertly navigated. NREL's femtosecond laser welds are not only sturdier but also present a cost-effective solution due to their hermetic sealing and robustness.

Future Outlook: With the progression of NREL’s research and the Durable Module Materials Consortium's commitment to lengthening solar panels' lifespan to 50 years and more, this innovative approach presents numerous environmental and economic benefits. The laser welding method promises a substantial reduction in production waste, aiming to make solar module recycling not just easier but also more efficient.

The NREL's innovation is not an isolated effort but part of a broader industry-wide push to enhance sustainability. The adoption and integration of this laser technology could spur more sustainable manufacturing practices and contribute to establishing a circular economy within the solar industry. By ensuring that more materials from solar panels are recovered and reused, the industry can greatly reduce its environmental footprint.

Structural Rigidity: One of the most significant challenges highlighted in the NREL research is the need for laser-welded modules to maintain structural integrity. Without the plastic polymers traditionally used as connectors between glass sheets, the modules need to be considerably stiffer to withstand external pressures. This is crucial for them to pass static load testing, which ensures durability and resilience.

Embossed Features on Glass: To compensate for the absence of the elastic properties of plastic polymers, NREL suggests modifications to the embossed features of rolled glass. However, this introduces a new set of production complexities. Modifying the glass's texture to provide the necessary stiffness without compromising the solar module's efficiency requires precise fabrication processes which may not be as mature or widely available.

Equipment Calibration: The femtosecond laser's efficiency lies in its precision, which requires finely tuned equipment. Misalignment and calibration issues can result in suboptimal welds or even damage the components, which could negate the benefits of glass-on-glass technology.

Cost Implications: Implementing femtosecond laser technology could also have cost implications. The investment in new equipment, training for personnel, and possible changes to the production line all translate into initial costs that manufacturers need to consider.

Scaling Production: The feasibility of scaling up femtosecond laser welding to meet the mass production demands of the solar industry is another hurdle. Transitioning from a proof-of-concept stage to high-volume manufacturing presents logistical and technical challenges that need addressing.

Technological Adaptation: The NREL research implies that existing solar module designs may need adapting to accommodate laser welding. The industry's readiness to implement these changes and the potential disruption it may cause to existing production techniques could be a limiting factor.

End-of-Life Evaluation: Finally, while femtosecond laser technology appears promising, extensive testing is required to determine how these modules perform at the end of their life and the actual benefits in recyclability. A full lifecycle analysis is essential to measure the true environmental benefits.

With the advent of laser technology in solar panel recycling, the future of the industry is looking brighter than ever. Imagine a future where solar energy is not only renewable but also its components are fully recyclable, considerably reducing waste, and making solar energy truly sustainable. This might sound like a utopian dream today, but with technological progress, it could soon be our reality.

As consumers and beneficiaries of solar energy, it's incumbent upon us to support and advocate for sustainable practices within the industry. By choosing to patronize sustainable energy providers and investing in companies that prioritize recycling, we can play an active role in promoting sustainability. Our collective efforts can help hasten the transition to a more sustainable future.

In conclusion, technological advancements like the NREL's femtosecond laser solution are pivotal in the quest for a sustainable future. Indeed, the French have already implemented several measures to recycle solar panels, a trend that is soon expected to become a buzzword in fashion circles. This raises a thought-provoking question: What else can we do to support the future of solar recycling? As we ponder over this, let's remember that each small step we take towards sustainability can help bring about a big change.