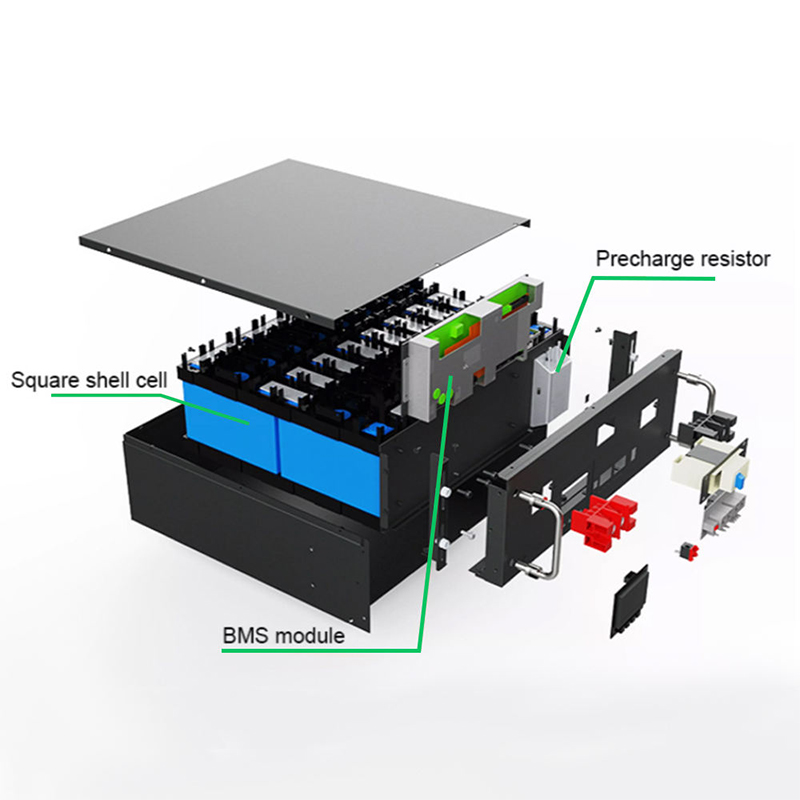

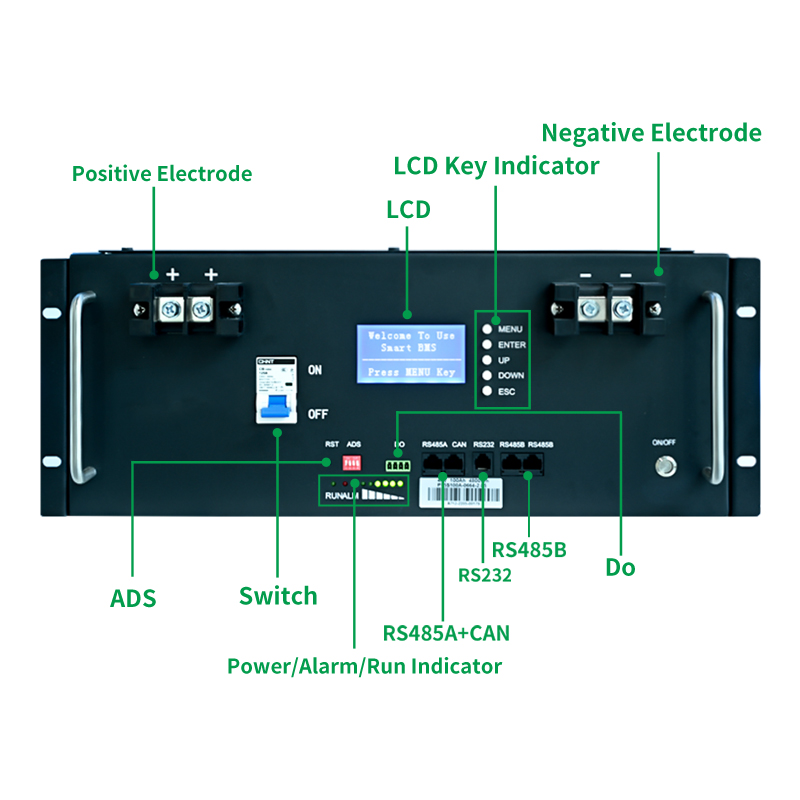

SunArk energy storage lithium batteries incorporate various safety features like battery management systems (BMS) for monitoring and controlling the battery's performance, protection circuits for preventing overcharging or overdischarging, and thermal management systems to maintain optimal operating temperatures. These additional components ensure the safe and efficient operation of the battery system.

Brand:

SunArkMax charging current:

100AOperation Voltage:

42-54VdcLife cycles (80% DOD, 25%):

6000 CyclesLithium battery standard:

UL1642.IEC62619.UN38.3.ROHS.CE-EMCOperation temperature:

20°C to 60°C @60+-25% Relative HumidityStorage temperature:

o°C to 45*C @60+/-25% Relative HumidityStorage time / temperature:

5 months @ 25°C. 3 months @ 35*C: 1 month @ 45°C

What are the components inside our rack lithium battery?

1. Lithium-Ion Cells: The heart of the battery is the lithium-ion cells, which store and release electrical energy.

2. Electrolyte: The electrolyte is a conductive solution or gel that allows the movement of lithium ions between the positive and negative electrodes during the charging and discharging cycles.

3. Separator: The separator is a thin, porous material that separates the positive and negative electrodes of the cell while permitting the flow of lithium ions.

4. Current Collectors: Current collectors are typically made of metal foils, such as aluminum for the cathode and copper for the anode.

5. Packaging: The lithium battery is enclosed in a protective casing to ensure electrical insulation and mechanical stability.

6. Terminal Connections: The positive and negative terminals of the battery allow for external electrical connections.

What's the main advantages of our lithium battery pack?

1. Voltage compatibility: Many modern power electronics systems and devices operate at 48 volts, making these batteries compatible with a wide range of equipment.

2. Efficiency: Compared to higher voltage systems, a 48V battery system can provide efficient power transmission and conversion.

3. Safety: Lower voltage systems generally have a reduced risk of electrical shock and are considered safer to handle and operate.

4. Scalability: 48V battery systems can be easily configured in series or parallel combinations to achieve higher energy storage capacities.

5. Cost-effectiveness: In many applications, 48V battery systems offer a good balance between cost and performance.

How about the componets to build a battery cell?

1. Positive Electrode (Cathode): The positive electrode is typically made of a lithium-based compound such as lithium cobalt oxide (LiCoO2), lithium manganese oxide (LiMn2O4), lithium iron phosphate (LiFePO4), or lithium nickel cobalt aluminum oxide (NCA).

2. Negative Electrode (Anode): The negative electrode is commonly made of graphite or other carbon-based materials that can intercalate lithium ions.

3. Separator: The separator is a thin, porous material that keeps the positive and negative electrodes physically separated while facilitating the exchange of lithium ions.

4. Electrolyte: The electrolyte is a conductive solution or gel that contains lithium salts dissolved in an organic solvent. It serves as the medium for lithium ion transport between the electrodes.

5. Current Collectors: Current collectors are usually metal foils, such as aluminum for the cathode and copper for the anode.

How do we produce the battery?

1. Determine the battery bank requirements: Calculate the desired capacity and voltage for your battery bank based on your application needs.

2. Select suitable lithium batteries: Choose lithium batteries that meet your requirements and are designed for use in a rack configuration.

3. Choose a racking system: Select a racking system that is designed for the specific lithium batteries you are using.

4. Prepare the rack: Install the racking system and ensure it is securely mounted and stable.

5. Connect the batteries: Install the lithium batteries in the rack, following any guidelines provided by the battery manufacturer.

6. Configure the battery management system (BMS): If your lithium batteries require a BMS, install and configure it according to the manufacturer's instructions.

7. Test and verify: Once the batteries are properly racked and connected, perform thorough testing to ensure proper functioning and performance.

FAQs:

Q1: Do you support OEM/ODM?

A:Definitely, OEM&ODM service is supported with a certain quantity,including customize logo,package and label;

Q2: What's the production time?

A: The production time is normally 15 working days. but we will always prepare some stocks for popular models.

Q3: Can you provide DDP service?

A:Yes, if you are a personal customer and don't want to deal with the customs, we can provide DDP service to your address.

Q4: What about the warranty and how to claim?

A: Warranty period are 10 years since you receive the battery, our professional after-sales team will deal with all warranty issues.