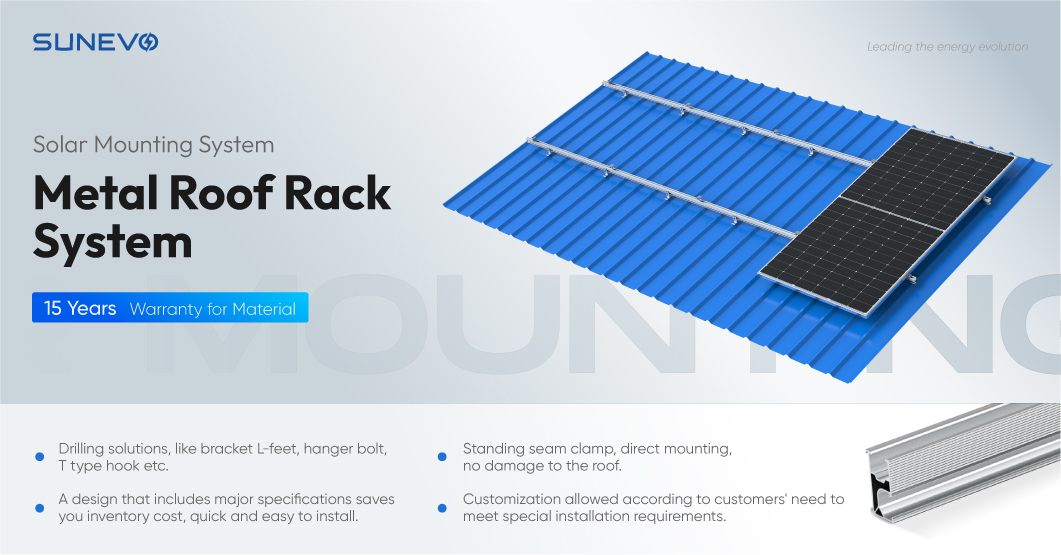

Metal roof solar panel mounting brackets refer to the structural components and accessories used to secure solar panels on metal roofs.

Brand:

SunEvoInstallation Application:

Metal Roof Rack SystemPV Module Layout:

Portrait or LandscapeWind Load:

60m/s or CustomizedSnow Load:

1.6KN/m2 or CustomizedInclination:

Parallel to the roofMetal Roof Aluminum Alloy Solar System Brackets Structure Mounting Systems

Metal roof solar panel mounting brackets refer to the structural components and accessories used to secure solar panels on metal roofs.

They are specifically designed to accommodate the unique requirements and characteristics of metal roofs.

These brackets ensure a secure and reliable installation while minimizing any potential damage to the roof.

Technical Features of Metal Roof Mounting Systems:

| Product name | Metal roof mounting system |

| Application | Metal roof |

| Inclination | Parallel to the roof |

| Material | AL6005-T5,SUS 304, EPDM |

| Finish | AL 6005-T5 Anodized, SUS 304 Shot blasting |

| Module orientation | Landscape or Portrait |

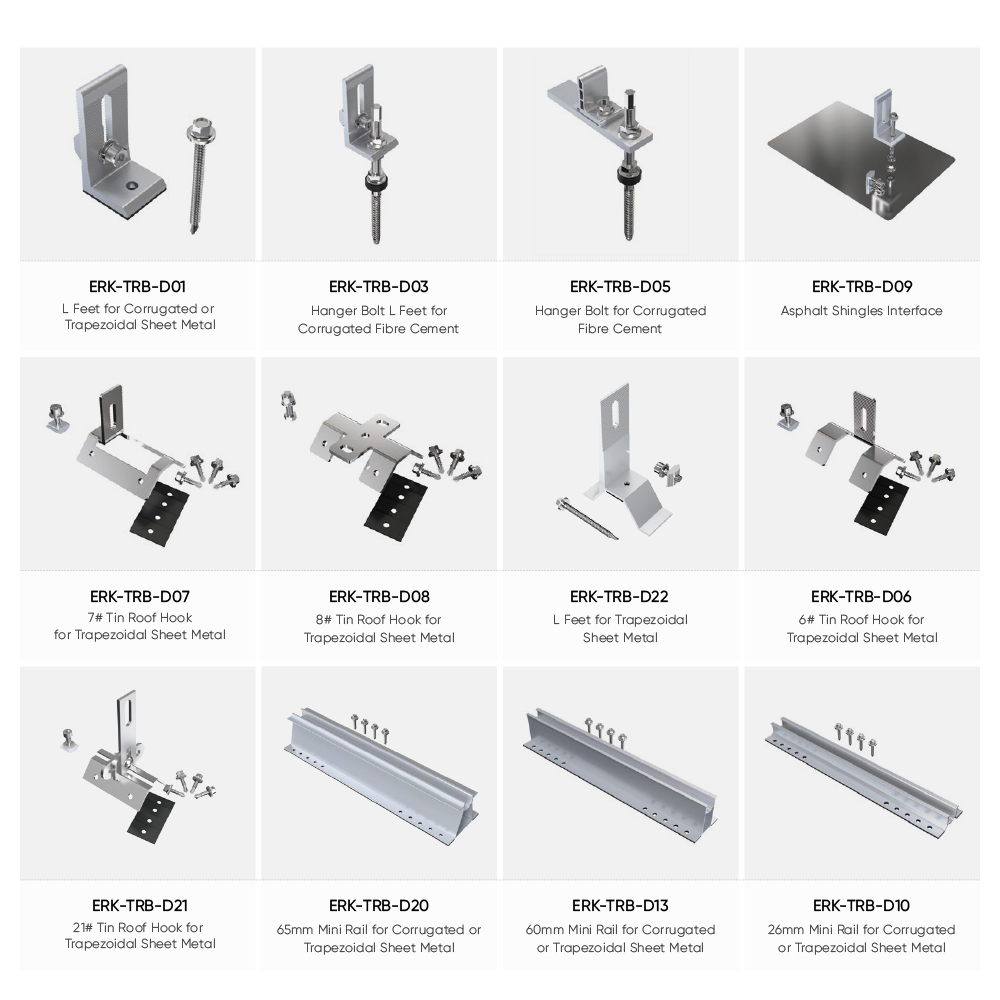

The components of metal roof solar panel mounting brackets typically include:

--Base Mounting System: This is the primary component that provides the foundation for the entire mounting structure. It attaches directly to the metal roof using specialized roof attachments like clamps or brackets.

--Rails: Rails are horizontal bars that connect the base mounting system and support the solar panels. They are usually made of lightweight, corrosion-resistant materials like aluminum or steel and are designed to withstand various weather conditions.

--Panel Clamps: These are used to secure the solar panels to the rails. Panel clamps come in various sizes and designs to fit different panel widths and thicknesses. They ensure a strong grip on the panels while allowing for easy installation and maintenance.

--Splice Kits: Splice kits are used to connect multiple rail sections together, ensuring a continuous and stable support structure for the solar panels. They provide structural integrity and prevent any potential movement or displacement.

--End Clamps: End clamps, also known as edge clamps, are used to secure the solar panels at the outer edges. They prevent the panels from shifting and provide additional stability during high winds or extreme weather conditions.

--Grounding Equipment: Metal roof solar panel mounting brackets should include proper grounding equipment to ensure the safety of the system. This usually involves grounding washers, lugs, and copper wire connections to create a path for electrical discharge.

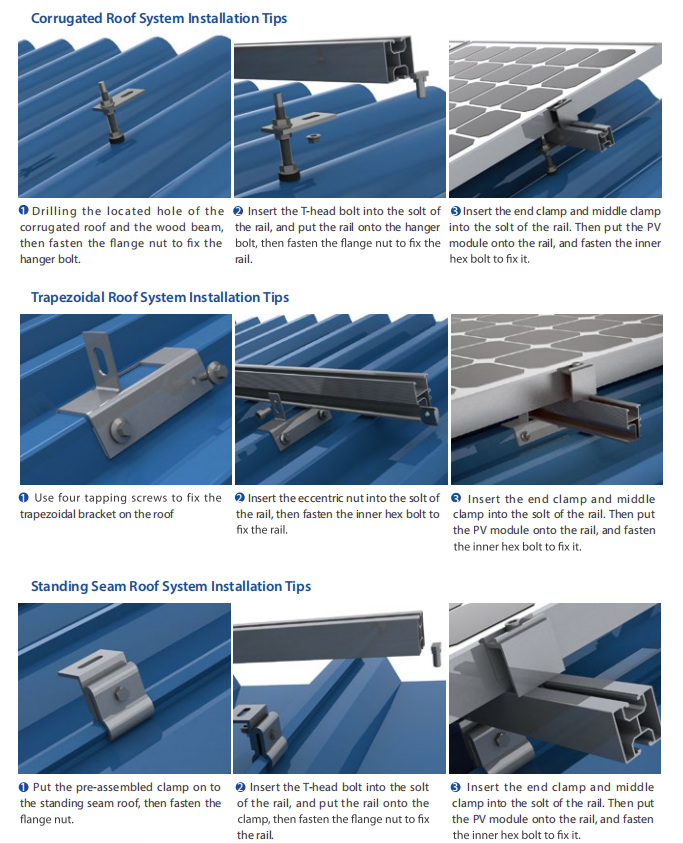

The Installation Process of Metal Roof Mounting Systems

The installation process for metal roof solar panel mounting brackets typically involves the following steps:

--Roof Inspection: Before installation, a thorough inspection of the metal roof should be conducted to assess its condition and ensure it is suitable for mounting solar panels.

--Preparation: The roof surface needs to be cleaned and free from any debris or obstructions. Any necessary repairs to the roof should be completed before installation.

--Layout and Marking: The precise location and orientation of the solar panels should be determined and marked on the roof. This involves measuring and spacing the mounting brackets accurately.

--Base Mounting System Attachment: The base mounting system is mounted onto the metal roof using appropriate roof attachments like clamps or brackets. The fasteners are tightened securely, ensuring a watertight seal.

--Rail Installation: The rails are then attached to the base mounting system, following the marked layout. They are secured firmly in place using appropriate fasteners.

--Panel Installation: Solar panels are then mounted onto the rails using panel clamps. The panels are positioned and aligned correctly, and the clamps are tightened securely to maintain a stable attachment.

--Connection and Grounding: Once the panels are installed, electrical connections between the panels and the system components, such as inverters and batteries, are made. Proper grounding equipment is installed to ensure electrical safety.

--Final Inspection: A final inspection is conducted to ensure the installation meets all safety and quality standards. The integrity of the mounting structure and the roof is assessed, and any necessary adjustments or improvements are made.

Installation Project Cases

It's important to note that the specific installation process may vary based on the type of metal roof, manufacturer guidelines, and local building codes. Therefore, it is recommended to consult with a professional installer or follow the manufacturer's instructions for a proper and compliant installation.